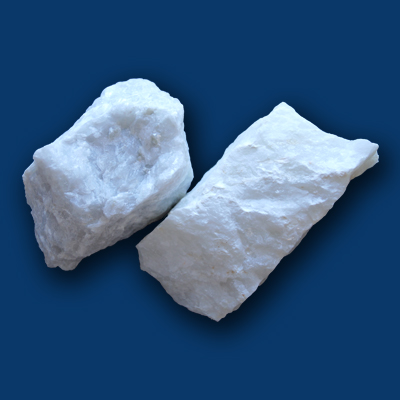

Calcite Powder/ Calcium Carbonate Powder

We manufacture Calcite powder of purity upto 99% CaCO3, to cater the demand and specifications of our valued customers. The name Calcite comes from the Greek word meaning Lime. This comes from its chemical component, Calcium Carbonate, which sometimes is mistakenly known as “Lime.” Calcite is known in more than 300 forms of crystals. Super white quality of Calcite in fine powder form is used in the manufacture of Paint, Distemper and Insecticides. It is also used in the manufacturing of Plastics, Cement, Calcium Carbide, Metal Polish and sometimes also as a fluxing agent.

We supply high grade Calcium Carbonate in the form of lumps as well as fine Coated and Uncoated powder as per Customer specs and requirements. We process Calcite upto 10 microns.

Information Table

| About Calcite | Typical Properties | Applications |

| Chemical Composition | Surface Treated Calcite | Properties of Surface Treated Calcite |

About Calcite

Calcite is the one of the most common minerals on earth. It occurs in a seemingly unlimited variety of shapes and colors. It constitutes a major portion of many of the earth’s rocks. Calcite belongs to the calcite group of minerals, a group of related carbonates that are isomorphous with one another. They are similar in many physical properties, and may partially or fully replace one another, forming a solid solution series. All members of the calcite group crystallize in the trigonal system, have perfect rhombohedral cleavage, and exhibit strong double refraction in transparent rhombohedrons.

Calcite and Aragonite are polymorphous to each other. Although Calcite and Aragonite contain the same chemical composition, they differ in crystal structure. Calcite forms trigonal crystals, whereas Aragonite forms orthorhombic crystals. Sometimes the crystals of Calcite and Aragonite are too small to be detected, and it is only possible to distinguish these two minerals by complex scientific optical tests. Since the true identity of microcrystalline forms of Calcite or Aragonite may not known, they may be mislabeled as the wrong mineral.

A microcrystalline type of Calcite in globular form is common in certain regions. This Calcite forms from precipitating calcium-rich water inside caverns or on limestone cliffs. It exists in the form of stalagmites, stalactites, flowstone, and strange globular growths. These growths constantly accumulate, forming layers. They are frequently impure, trapping in organic matter such as leaves, twigs, and moss as they accumulate. Because of their impure status, they are classified by some as rocks. These calcareous growths have designated names based on their shape, habit, or formation. Most of these growths are Calcite, but some are crystallized as Aragonite. The environment of formation, however, can be a key guide to whether the mineral crystallized as Calcite or Aragonite. Aragonite will generally develop only at hot springs, whereas most other calcareous growths will be Calcite.

Calcite may form as an undesirable coating on top of another mineral. The calcite can be easily burned off by soaking it in acid, which will cause it to effervesce and eventually dissolve, leaving the mineral below exposed.

Typical Properties

- Higher flow properties

- Higher mechanical properties in thermoplastic applications

- Better gloss and whiteness in Paints & Powder coating applications

- Excellent dispersion properties

- Prevents chalking

- Better corrosion resistance

APPLICATIONS:

- PP master batches, Automotive & Furniture compounds

- LDPE masterbatches

- Rigid PVC Pipes

- Leather Cloth Industry

- Paints, Inks, Powder Coating & Ceramic Industry

- Rubber Industry

- As a flux in Glass Industry & in sizing of Textile goods

Our grades of Calcite powder are available in 300 Mesh to 700 Mesh BSS standard & in Micronise grades, Our grades are available in top cut 5, 10, 15 & 20 Microns.

Chemical Composition

- CaCO3 90% to 97%

- MgO 1.5% to 2.5%

- Silica 1 % to 3.5%

Variation of the specifications stated due to natural raw materials & environment conditions are possible. though they have no influence on the application properties described.

Surface Treated Calcite :

We also do coating on Calcite powder. We provide coating of Steric Acid. The Coated Calcium Carbonate powder is used in plastic compounds manufacturing to avoid moisture contains. Coating is done from 1% to 3% or as per customer requirement.

Properties of Surface Treated Calcite:

- Rapid and complete dispersion

- Low abrasion at higher loading

- Low moisture content

- Good compatibility with Polymers & other additives

- Increased flow rate

- Reduced plasticizers & other additives

- Better HDT

- Better Impact strength

- Better dispersion

- Lower raw material cost